Making a full-colour print on paper was once a costly and time-consuming process, but nowadays, cheap full-colour prints roll off affordable Inkjet printers in seconds. However, it is not widely known that 3D printers have also entered the full-colour era. With the Mimaki 3DUJ-553, it is possible to print very complex and realistic 3D objects in as many as 10 million colours.

Written by: Bert Benckhuysen, senior product manager at Mimaki EMEA

Biologically, the human eye can only see three colours; namely: red, green and blue. However, the different cells in the retina are also able to see the presence of light and perceive different wavelengths. This information is combined through an almost magical process in the brain, allowing us to interpret millions of colours. Colour is magical, and that is the magic that creates the enormous difference between a standard mono-colour 3D print, or even one in primary colours, versus one in full-colour. So, let us look at the advantages that this revolutionary step brings to 3D printing.

Vivid colours

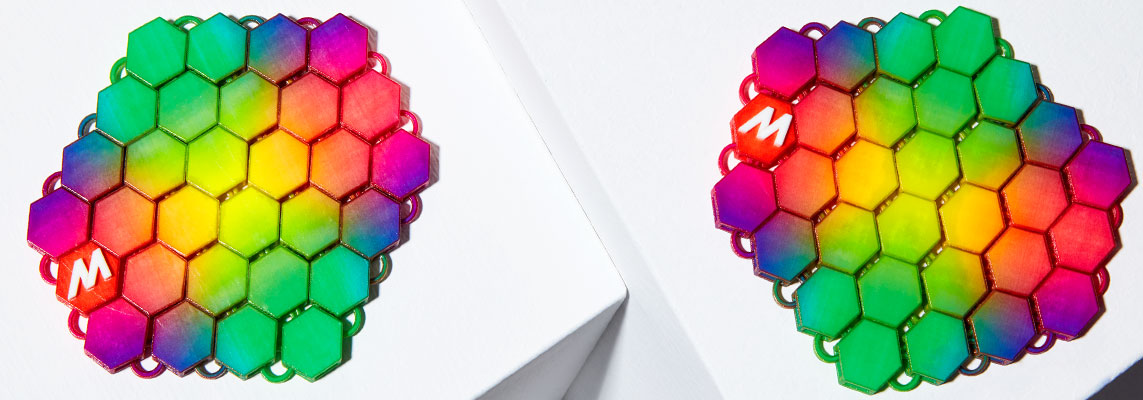

The use of colour is particularly functional in a 3D print with one or more primary colours. It helps to distinguish different components by making contrast or (textual) markings visible. But a 3D model really comes to life if you can print in up to 10 million colours. You only need to think of realistic skin and flesh colours for printing medical models and statuettes as an example. It allows you to visualize reality in a way that was previously only possible after extensive craftsmanship. But the fact that you can use vivid, vibrant colours when printing a 3D model, even colour-accurate based on an ICC profile, is revolutionary. It is therefore no longer necessary to manually paint a printed object in the right colours; it can be delivered directly to the customer as soon as it is printed!

Less post-processing

In many cases, post-processing is a considerably labour-intensive component of 3D printing. Many 3D printed models must undergo extensive processing after printing is completed, including removal of supporting material, sanding, spraying, painting and UV coating. With Mimaki, both colour and UV treatment are part of the printing process, but that is not all. In addition, water-soluble support material is used in printing, so a tub of lukewarm water is sufficient to ready a printed object for a customer. There is no additional manual work involved, and there is no risk that small details will fade or break off when removing the supporting material.

High quality

With full-colour 3D printing, some manufacturers use a technique based on fine layers of powder that are cured using different techniques. This results in objects that are admittedly colourful, but the detailing is limited, and the firmness leaves a lot to be desired because of the technique used. Mimaki chose to use Inkjet technology in its 3D printers with a drop size of only 19 microns. This makes the printed models very detailed, colour-fast and, moreover, the strength of the material is also comparable to ABS. With a Mimaki printer, printing a 3D model is truly What You See is What You Get (WYSIWYG): a magical process in which a colourful, lifelike 3D model rolls from the printer directly in quantities as low as one driven by an easy-to-use software suite and requiring minimal post-processing. It’s truly a magical revolution.